INDUSTRIES

LITERATURE

Download our documents to see specific data of the product and how it can work for you.

LEARN MORE

If you have any questions regarding our products or services, please do not hesitate to contact us. We aim to respond to all inquiries within 1–2 business days. Alternatively, you may call us directly to speak with one of our representatives.

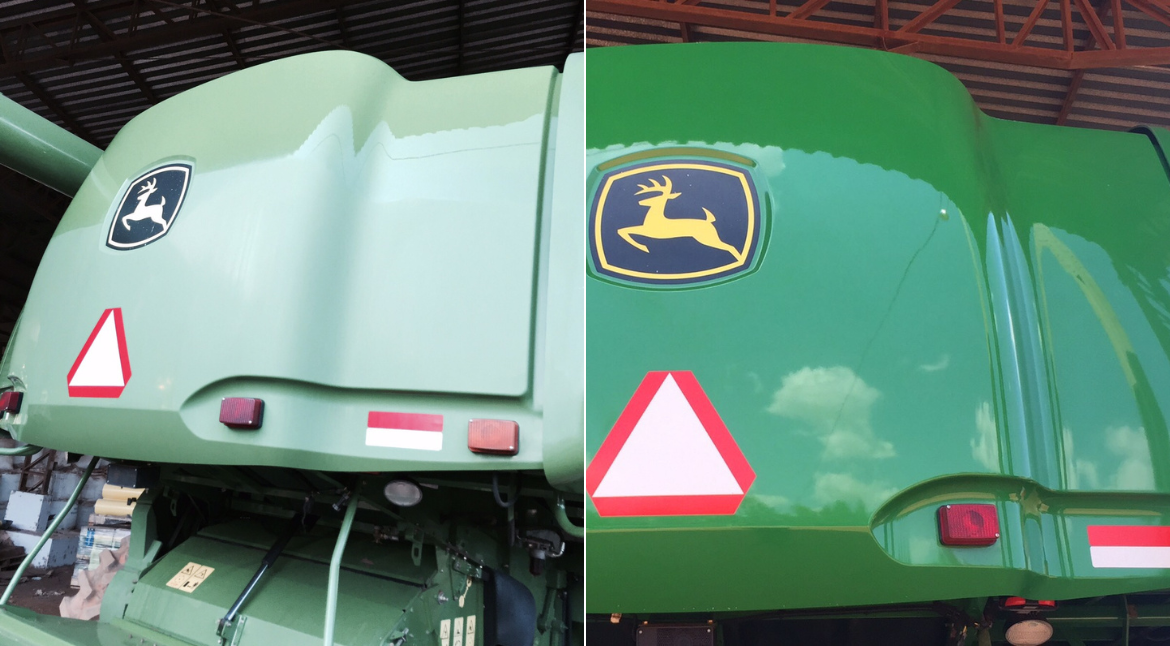

EXTEND SERVICE LIFE AND INCREASE THE PERFORMANCE OF YOUR FLEET

Our industrial coatings are the most advanced and effective solutions available to protect your vehicles and equipment.

These valuable assets are fundamental to your business. You can depend on our products to minimize surface wear & tear caused by exposure to the elements.

“Nano-Clear® NCI is a single-component, humidity-cured, highly cross-linked, polyurethane hybrid nano-coating system – designed to provide permanent protection. Its high concentration of chemically bonded polymers penetrates deep into the pores of newly painted, epoxy coated and highly oxidized painted surfaces.”

When it comes to protecting your assets, don’t settle for inferior products. Unparalleled in features and performance, Nano-Clear® coating products are guaranteed for an industry-leading 10 years, with longer term protection anticipated under normal operating conditions!

PRODUCT FEATURES

Nano-Clear® products will:

restore surface lustre and vibrancy

protect against corrosion, abrasion, chipping and UV degradation

greatly increase the durability and resilience of surfaces to the effects of weathering

protect your structures to a considerably higher degree than any other competing products on the market

PRODUCT BENEFITS

maintain the appearance by protecting your paint from loss of colour and gloss

greatly reduce the damaging and sometimes catastrophic effects of corrosion

protect your assets from mechanical damage including impacts and abrasion

reducing cleaning cycles and efforts

increase the lifespan and service life of your fleet assets

help maintain the value of your fleet over time and potentially lessen depreciation

offer unmatched protection for items that are more prone to the effects of material degradation

enhance the impression and experience clients have when your fleet arrives at the job site

save time and money by dramatically decreasing the number and frequency of maintenance efforts

For the last 30+ years, coating chemistries have been variations on the same (linear chain) polymer themes. As a result, industrial customers are on an endless treadmill: Painting, then watching the subsequent oxidation, loss of gloss, corrosion, and paint failure… requiring in turn, labour-intensive surface prep and repainting with the same conventional coating technology.

NCI dramatically improves resistance to corrosion, weathering, abrasion, scratching, chipping, marring, chemical, and UV degradation. We achieve these industry leading levels of protection by incorporating polyurethane, polyuria pre-polymer and polysilane into a molecule dense 1K product. What makes NCI 1K additionally so unique is our extreme protection requires no activators, hardeners, or accelerators in the application process, making Nano-Clear ® extremely applicator friendly.

Nano-Clear NCI is also designed to be applied directly over freshly coated surfaces including 2K epoxies, 2K polyurethanes and powder coatings. No matter how badly oxidized your existing coating is, Nano-Clear NCI will restore its colour and provide unmatched surface protection.

Nano-Clear® is manufactured using proprietary, highly cross-linked, 3D polymers which are engineered to enhance, restore, protect and extend the surface life of commercial and industrial coated assets for a minimum of 10 years from day of application.

NCI Is a one component (1K), humidity cured, multifunctional, protective clear topcoat. As a clear topcoat, NCI will chemically and mechanically bond to new and oxidized two component (2K) commercial and industrial epoxy coatings, polyurethane coatings, powder coatings, fibreglass, gel-coats, coated composite materials, select composite materials, latex, and anodized aluminum.

Put simply: NCI restores the colour, gloss, surface hardness and extends the surface life of conventional coatings by 10 years.

HOW IT WORKS

Nano-Clear® penetrates deep into the smallest pores of newly painted (curing) or highly oxidized coated surfaces to form a densely cross-linked / hard surface.

Nano-Clear® provides dramatically higher crosslink density over conventional one and two component (1K / 2K) industrial coatings. Crosslink density is defined as the concentration of chemical bonds within a polymer.

The higher crosslink density within the Nano-Clear® polymer matrix results in an increased enhancement of its physical and corresponding multifunctional properties.

AN AWARD WINNING SOLUTION

Nano-Clear® Industrial (NCI) Coating systems, with over 16 years of innovative development, was recently presented as the winner of the prestigious “NACE MP Corrosion Innovation of the Year Award” – Coatings & Linings category.

Nominees were “rated by a panel of leading corrosion experts spanning multiple niches across the industry. All innovations had to demonstrate the potential for a significantly positive impact on corrosion control, prevention and mitigation by improving an existing corrosion-control solution, or by providing a new solution where none previously existed. It was also necessary to demonstrate that the innovation performs as described with supporting documentation from laboratory or field results.”

“Nano-Clear has outperformed 6 layers of the (current) stone guard. ProGuard Canada has also indicated that the hardness of Nano-Clear® can be further increased beyond the hardness rating of 4H. Using the updated Nano-Clear stone guard, and with the addition of another layer, a further decrease in stone chips could be seen (realized). As Nano‐Clear® has significantly reduced the number of stone chips to the front bumper, and has proven to be a more resilient stone guard, Engineering recommends that future bus deliveries, and buses that go out for refurbishment have the NCI stone guard applied."

Fleet Engineer | Metrolinx / GO Transit

“We initially heard about Nano‐Clear Industrial (NCI) coating from one of our Berkshire Hathaway sister companies and how much they liked it. Shortly thereafter, we ordered NCI and put it to the test. We picked a handful of cranes where the paint was heavily faded and spray-applied the NCI. Being very impressed with the initial results, we then proceeded to test additional cranes. One of the initial concerns we had was if NCI was going to hold its shine and not fade out after a year or so. Nano‐Clear has performed as advertised as these crane units continue to look as good as the day we applied Nano‐Clear® (2 years ago). One of the things I'm most impressed with is how easy it is to use. Simply wash, degrease, mask and spray-apply the NCI. By using NCI, we've saved thousands of dollars restoring vs. repainting our cranes. We look forward to continuing the use of Nano‐Clear.”

Al MacDonell | Sterling Crane

"We have used and applied Nano-Clear on our energy plants and machinery and we are pleased with the quality and results of the coating on our surfaces. Surfaces coated with Nano-Clear are easier to clean, maintain and stay in better conditions for longer."